Plywood is a material created from some thin veneer panels whose size is same and thickness is about 1mm.

These layers of wood are arranged perpendicularly in the direction of the wood grain then glued and compressed under heat to form a strong sheet.

Since the 1980s, Americans had invented a way to press thin layers of veneer on top of each other to create thicker and stronger boards that are more economical than solid natural wood while remaining its qualifications. In Vietnam, Plywood at first was applied to make kitchen cabinets, furniture ... until the last 10 years, when this material has been used for flooring.

CHARACTERISTICS OF PLYWOOD FLOORS

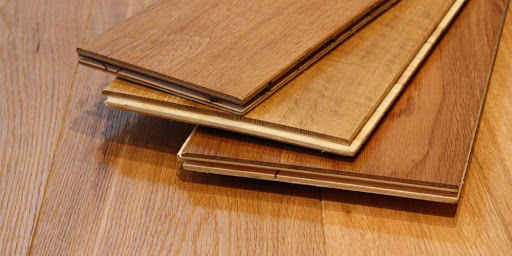

As mentioned above, the structure of Plywood contains some layers of natural wood slices (veneer) about 1mm thin together, these layers are arranged in staggered direction of the wood grain. The thickness of plywood board varies from 3mm to 25mm depending on customer’s requirements. The number of the layers of a plywood board must always be odd (3, 5, 7, 9…) so that the board will have a core layer in the middle, and there will be the same grain orientation in the two outer layers of the core layer. This helps these layers restrain each other from warping or cracking.

Natural wood has a major drawback that is expansion, warping, and shrinking over time. Normally, natural wood often expands horizontally, when placing staggered layers of plywood perpendicularly in a plywood board, the vertical wood panels will fix the horizontal panels, making these panels unable to expand nor shrinkage, thereby solving the problem of natural wood floors.

In put materials for Plywood are usually short-term wood species such as pine, birch, acacia, eucalyptus, durian…

ADVANTAGES AND DISADVANTAGES OF PLYWOOD FLOOR

Advantages of plywood flooring

Friendly to the environment and user

The raw materials of plywood are short-term woods, grown for exploitation such as eucalyptus, rubber, etc., so they do not affect the primary forest and destroy the environment. In the meantime, while plywood material is 98% natural wood (the remaining 2% is glue with low Formaldehyde content, within the safe standard frame), thus it is very user-friendly and safe.

Water resistant: Plywood flooring is water resistant up to 24 hours

High stability: staggered layer structure helps the floor not to warp, shrink when the temperature changes, high capability of moisture resistance.

The surface can be changed at will because Plywood is a type of floor with a smooth surface that is easy to adhere to. You can choose flexible floor surface such as Veneer, Laminate or Melamine.

Competitive price: Compared to other types of laminate flooring, the price of Plywood flooring is considered to be quite cheap, it’s even much cheaper than German or Swiss wood floors, but the quality is still guaranteed, this helps users to save costs.

Disadvantages of Plywood Flooring

The durability and strength of plywood floors are not as high as that of natural wood floors

Lower fire resistance than other industrial floors

SURFACES OF PLYWOOD FLOORS

Based on the material that is used to cover up the surface, plywood floors can be divided into the following types:

- Plywood floors faced veneer

- Plywood floors faced Laminate

- Plywood floors faced Melamine

Plywood floors faced veneer: 90% similar to natural wood floors. Veneer is thinly sliced from round logs, thus it remains whole characteristics of the tree, the color and texture are beautiful and carries the soul of nature. It is said that the veins of the tree to be like the fingerprints of each person, it is one of a kind, no tree is the same. After being sliced and processed, the veneer sheet is pressed onto a plywood board to form a veneer-covered plywood board. Plywood floor faced veneer has a very high aesthetic value due to its natural wood vibe, quality and authenticity. The cost of this type is also higher than other types of artificial surfaces but lower than monolithic natural wood flooring.

Plywood floors faced Laminate: Laminate, also known as Formica, is an artificial material consisting of many layers, including a layer of decorative paper, created by using modern printing techniques. Its color and texture is look alike to real wood. On the surface of the laminate is coated with a water-resistant and scratch-resistant layer to increase the durability of the product. The price of this product is lower than veneer one but higher than melamine surface.

Plywood floors faced Melamine: this is a fairly affordable flooring material. However, this product line has low durability, users should consider before installing because the costs incurre after dismantling the floor and reinstalling are quite high.

HOW TO IDENTIFY A GOOD PLYWOOD FLOOR?

First: observed with the eyes and hand, a good Plywood floor must have a smooth surface when you touch it. The panels that are pitted, include wood fibers on the surface, etc., will make you feel rough when touching and also causing discomfort when moving.

Second: the layers of plywood cores must be uniform, with equal thickness to ensure uniform distribution of impact force. Panels with uneven layers also lead to easy warping and swelling because they are not flat, creating spaces for the wood to expand.

Picture: An unqualified Plywood

Picture: An unqualified Plywood

Third: the layers must be closely linked together, tightly sealed with no gaps to ensure that the floor does not peel off when absorbed by water or impact force. The slits also create conditions for dirt to enter, it will form stubborn stains that are unsightly and contain many potential health risks.

Last but not least: the plywood floor surface must be smooth, free of cracks and grooves. Specially, for veneer floor, you must observe carefully to ensure aesthetics and the ability to prevent water from seeping from the surface and dirt from entering the slots. It is best to choose floors that are covered with a surface that has protective layer against scratches and water.

IS PLYWOOD FLOORS EXPENSIVE?

The price of plywood floors is not expensive; in fact, it is suitable for many basic needs of users. This product inherits natural beauty of solid wood floors, user- friendly (because it uses less glue and chemicals than other types of other industrial flooring). Another plus point is that using plywood flooring will help saving forest resources, reducing chemicals used, contributing to improve the ecosystem and preserving the living environment of future generations.

Buon Ma Thuot veneer is proud to be a manufacturer of high quality veneer and plywood flooring faced veneer. Please feel free to contact us any time.

Contact us to get the latest quotation or supports at

- Hotline: 0969389068

- Email: info@bmtveneer.com

- Website: veneerbmt.com\

Picture: An unqualified Plywood

Picture: An unqualified Plywood